How To Make Hempcrete?

Hemp hurds refers to the inner-core fiber of the hemp stalk – there is three types of hemp fiber, Hurd, Green microfiber and Bast fiber.

Hemp hurds refers to the inner-core fiber of the hemp stalk – there is three types of hemp fiber, Hurd, Green microfiber and Bast fiber.

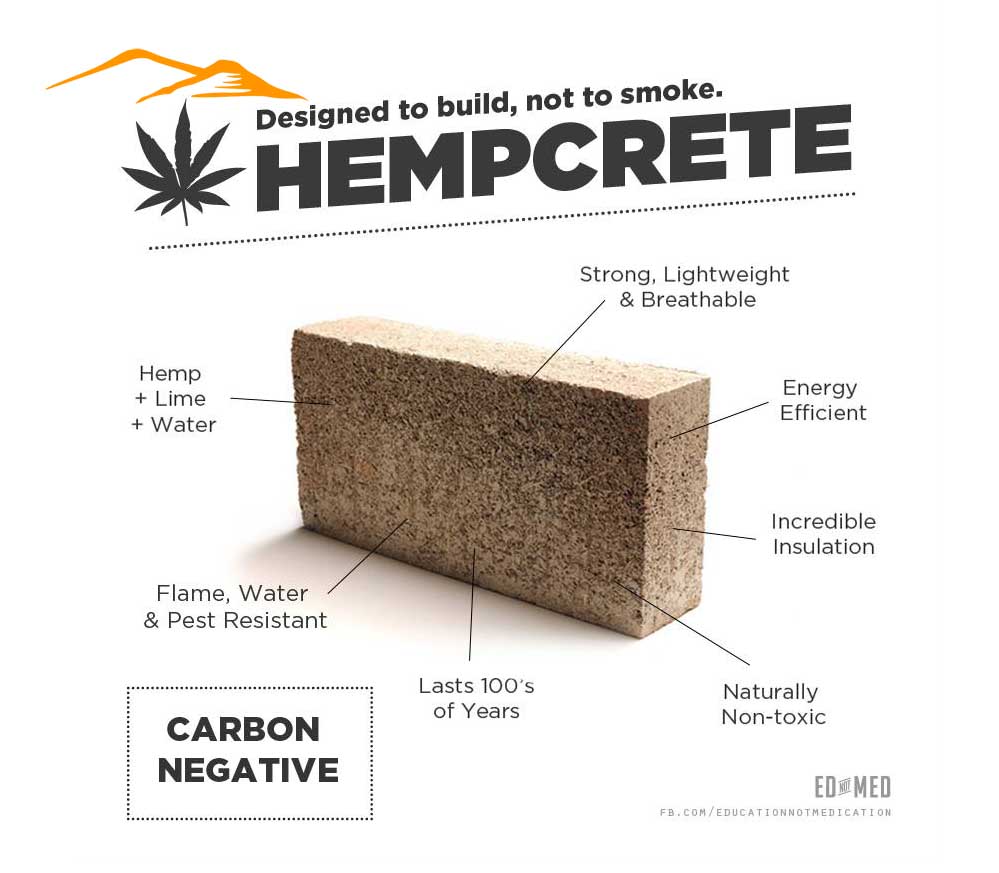

It takes only three (3) materials to create hempcrete: which is (1) hemp hurds (or “shives”), (2) lime binder, and (3) water.

Hemp hurds are the woody inner parts of the hemp stalk. They are first broken into fragments and separated from the fiber by way of breaking and scutching separating impurities from raw materials by using a machine called scutcher.

The lime which is used in the mixture acts as a binder. Hemp hurd contains a high silica content that helps it to bind well with lime.

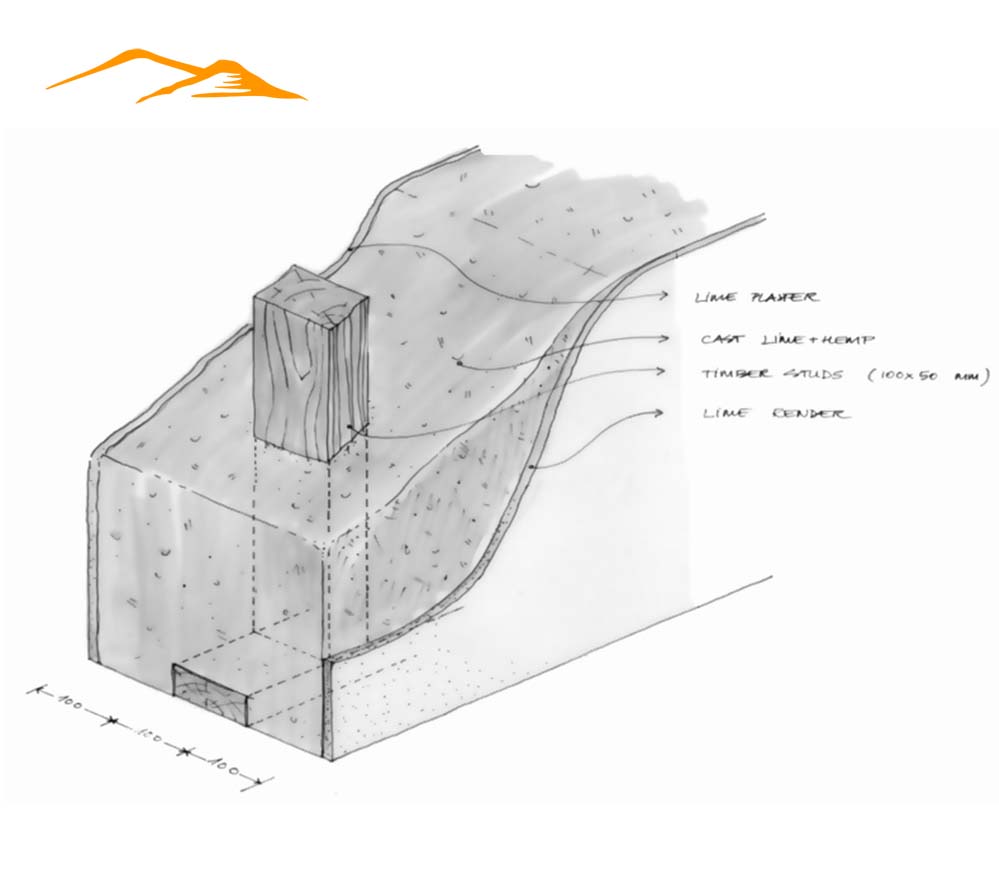

Hempcrete has a λ value (conductivity which the rate of the passage of heat through the material) of ~0.076 – 0.11 W/(m.K) when mixed with a mild to moderate hydraulic lime consisting of ~85% hydrated lime and ~15% clay or pozzolans.

For Floor Slabs, a more hydraulic lime is used and sand is added to improve strength and water resistance λ value ~ 0.13 W/(m.K).

For the Ceiling Insulation and the internally insulating stone wall coating, a pure hydrated lime is used and a higher percentage of hemp to provide a more insulating and lighter mixture λ ~0.08 W/(m.K)

The mixing of hemp lime mostly depends on the size of the building. It is mixed in a large forced action pan mixer. If you have to mix small amounts, you can do so in a conventional drum cement mixture. It is very important to know the exact proportions and mixing techniques. The proportions being used vary with the type of binder that you are using to bind the materials.

You can use the ratio of 4:1:1: 4 buckets of hemp hurds, 1 bucket of water and 1 bucket of lime.

Here are the steps you can follow to mix the materials.

(1) Add water into the mixer.

(2) Add lime binder into the mixer.

(3) Let the water and lime mix to a slurry

(4) Add hemp hurds to the mixer and allow it to mix properly

(5) Tilt the mixer to get an even mix.

(6) As soon as the hemp hurds are mixed, stop the mixture.

(7) Rotate the mixture and use your hands to clean the mix and if not mixed properly rotate it for few more seconds.

In order to test the mix, form a ball of mixture in your hand and squeeze it. If the ball breaks in two portions, it is perfectly mixed. Empty the mixer and use your hands to scrape off the last bit of hempcrete. Your mixture is now ready to be used for hempcrete construction.

Our organic hemp farm provide direct, local hemp hurd and hemp fiber at wholesale prices. 100% grown and processed in Colorado. Get the highest quality USA grown hemp hurd or hemp fiber directly from the at the lowest cost available.

We have a partnership with Coyote (UPS) to deliver your hemp hurds to you with GPS tracking, refrigerated and liability insurance, in all 50 states.

Use hemp hurd or fiber by the ton for paper, hempcrete, insulation, fibre board. Wholesale hemp hurd and fiber direct from our farms and processors.

Powdered Hemp Hurd is green microfiber used for beauty products, nutritional products. Hemp is just more sustainable for the environment in longevity, durability and strength.

Hempcrete or hemplime is biocomposite material, a mixture of hemp hurds (shives) and lime, sand, or pozzolans, which is used as a material for construction and insulation.